Introduction to Beef Jerky

Beef jerky, a popular snack made from lean cuts of beef, has a rich history intertwined with traditions of preservation. Its production process not only enhances flavors but also increases the meat’s shelf life. Understanding the intricate steps in beef jerky production is essential for both enthusiasts and producers alike.

The Beef Jerky Production Process

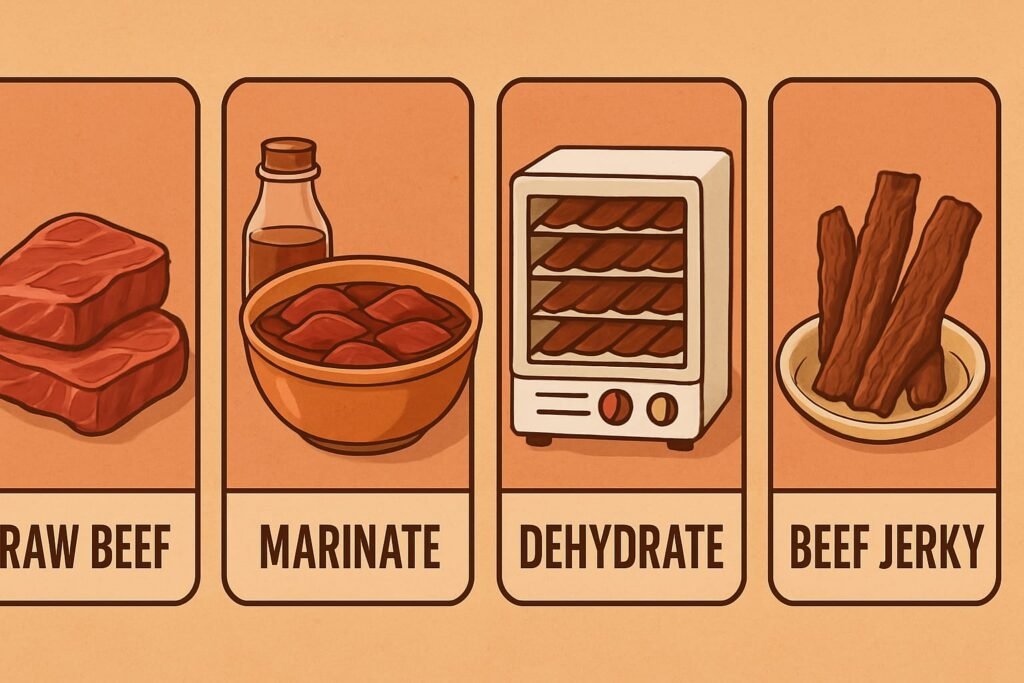

The production of beef jerky begins with selecting the right cuts of meat. Ideally, lean cuts such as flank steak or round steak are chosen to minimize fat content. After trimming and slicing, the meat undergoes marination, where a blend of flavors is infused into the beef. Typical ingredients include soy sauce, Worcestershire sauce, garlic powder, and even sugar for a hint of sweetness.

Dehydration: The Key to Longevity

Post-marination, the next critical step in beef jerky production is dehydration. This process is vital as it removes moisture, thereby inhibiting bacterial growth and allowing the jerky to be stored for long periods. Dehydrators or oven methods are commonly used, with temperatures kept higher than 160°F to ensure safety. The finished product is chewy, flavorful, and packed with protein, making beef jerky a favored snack among many.

In conclusion, the careful selection of meat, effective marination, and thorough dehydration are pivotal elements in beef jerky production. Whether for personal enjoyment or commercial purposes, mastering these stages can lead to creating delicious jerky that captivates the taste buds.